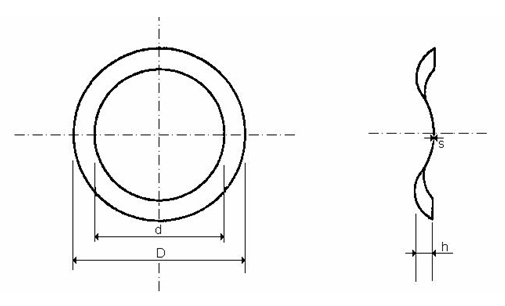

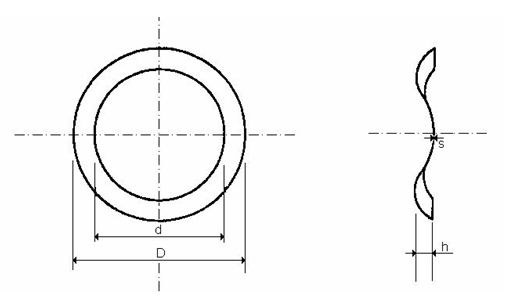

We offer wave spring washers and shim washers for electric motors (in carbon steel and on demand in stainless steel), both standardized and also customized (particular dimensions or loads according to Customer’s needs).

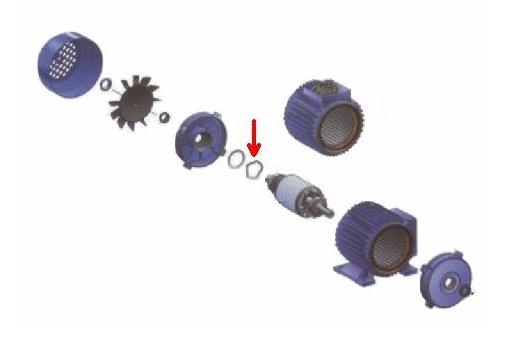

The wave spring washers produced by Filtomatic are used in rotating machines (for example in the electrical motors) with the aim to reduce the noise of the rolling elements.

As well as the bearings become in the last years more and more precise and reliable, also the wave spring washer had to improve its features.

Thanks to the wave spring washers the bearings could get:

- Higher speeds

- Lower and lower noise and vibration levels;

- An increase of strength and consequently an increase of the lifetime even used in critical conditions.

Thanks to these improvements, both of the bearings and of the wave spring washers, electric motors has become more and more performant.

The noise of electrical motors starts when the bearing balls lose the correct bearing race; this tolerance can be corrected using our wave spring washers LMKAS.

The wave spring washer will apply a pressure on the external ring of the bearing in order to obtain a silent smoothness. The expansion of the motor shafts forces the ball bearings to big axial loads, that damage the same bearings and increase the noise of the electrical motor. Using the wave spring washers produced by Filtomatic the motor shafts can expand without damaging the rolling elements and their case.

The wave spring washers can correct the eventual interaxial mistakes that may happen during the building of the electric motors. The hammering and vibrations are often the cause of the wear of ball bearings: using the wave spring washers LMKAS play a great role as shock absorbers so that this inconvenience can be easily stopped.

The wave spring washers are also successfully used in machine tools – as for example in the head of the grinding machines – in pumps, speed reducers, pneumatic and hydraulic motors. Filtomatic is also specialized in the production of their shim rings:flat rings of different thicknesses and of the same diameter as the wave spring washers – to “adjust” them to every case.

The wave spring washers LMKAS produced by Filtomatic come from carbon steel C67 strips, according to the norm UNI 10132-4 (cold rolled strips in carbon steel).

To purchase the raw material used to produce the wave spring washers we address only certified Suppliers – who adopt a Quality System according to internationally valid norms that grant an high quality standard as Filtomatic itself (since 1999 certified according to the norm UNI EN ISO 9002 and then according to the norm UNI EN ISO 9001:2015).

The compression loads, to which the ball bearing can be submitted are called: Constant Load and Maximum Load. They are obtained carrying out hundreds of tests on different production batches and after having strained the ring with 3 compressions to the same height to the thickness + 0,1 mm (after several tests we found out that the height and the load become constant after 3 compressions).

We can assure a deviation of load on our wave spring washers that doesn’t go beyond the 20% of tolerance; on demand we can also grant the 5%.